The most terrible thing could be in concrete is any signs of wear and tear. Wear and tear grows with time to time. This small crack may turn out to be a big opening out crack is creating a concrete dilemma for construction companies, and that cost large amount of maintenance and repairs. So never let any signs of wear and tear go for 'Self-healing concrete' as they can lower down cost much lesser to repair in the future.

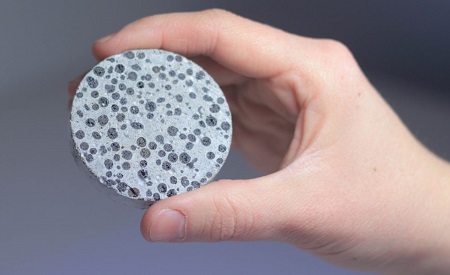

Self-healing concrete is mostly defined as the ability of concrete to repair its cracks automatically. It is also called self-repairing concrete. strength of concrete is impaired by the liquids and gases that potentially include Bacterial substances. Bacterial self-healing concrete targets the crack healing and the recovery of water-tightness.